Micanite types

Micanites, is a group of materials based on natural and synthetic mica. Characterized by its original advantages (thermal and dielectric resistance), but allow you to overcome the drawbacks of mica (fragility, the difficulty in obtaining large size and complex shapes).

The basis for the production of micanite is mica paper, which is then impregnated with resin using a high pressure and high temperature.

Mica paper is produced from high quality muscovite, phlogopite or synthetic mica in the hydrolytic separation (water at high pressure, breaks mica plates on a flat mica flakes with a thickness of several microns) forming the first stage the mica pulp compressed in the form of thin paper, which after drying is wound onto a roll. Even in this embodiment may be a commercial product (see. here).

In a next step, the paper is impregnated with resin, and the layers can be combined to form a laminate. Due to the small amount of resin micanite keeps the advantages of mica shown in its natural state. At this stage is possible to create micanite with different properties by:

- choice of used mineral - phlogopite, muscovite, synthetic mica,

- choice of paper weights, thickness and amount of layers,

- selection of the type and amount of binder - acrylic resin, epoxy, silicone etc..

- the use of additional substrate: glass fiber cloth, mat polyester, polyethylene, ceramic felt etc.

Generally, micanites are divided into two groups:

- commutator micanite - impregnated with epoxy resin,

- heating micanite - impregnated with silicone resin.

Commutator micanite

This type of material is formed by compressing the mica paper saturated with epoxy resin at elevated temperature. The result is an electrical insulation material with properties depending on the type of natural mica used in the mica paper (muscovite, phlogopite).

Material name comes from its main applications: as insulation in commutators of electrical machines (motors, generators, etc). Besides commutators is also used as a flat insulating plates (shims, spacers, etc.) in low temperature applications. Operating temperature of commutator micanite is 200 °C (temporary up to 400 °C).

Commercially, commutator micanite occurs most frequently in the form of plates or the elements cut according to customer's needs. In commutator's applications must be used higher accuracy of the thickness and polished surfaces of the plates.

Heater micanite

This type of material is also prepared by compressing a mica paper impregnated with silicone resin at high temperature, but using mica paper resistant to high temperatures (eg. thick flaky muscovite and phlogopite or synthetic mica) and the surface of the material additionally covered with silicone resin. Thanks to this, heater micanite can operate at temperatures up to 500 ° C (muscovite) and even 750 °C (phlogopite). It is non-flammable and has excellent dielectric properties.

Resistance to high temperature determines the range of applications heater micanite. These are mainly insulation heating elements and brackets in furnaces, heaters, dryers, toasters, etc, and insulation in presses and thermoset injection molds.

Commercially is present in the form of plates with dimensions such. 1m x 1.2m (there are also other sizes, see here) and a thickness ranging from 0.1 mm to 100 mm. Properties and commercial information on micanite plates are available later in this chapter (see. page Micanite plates).

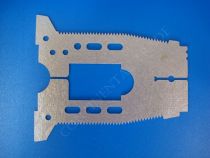

Heater micanite very is well machined using standard tools: saws, drills, milling machines etc. Special equipment is not required, but is recommended to use the tools of high-quality carbide and dust collection equipment.

On request we can provide micanite plates cut in complex shapes according to customer's drawing eg. as support heating elements or insulation pads (see here). In this case, please contact us.

While every attempt has been made to verify the source of the information, no responsibility is accepted for accuracy of data.